Calcium Carbonate Is Reshaping the Plastic Composites Industry

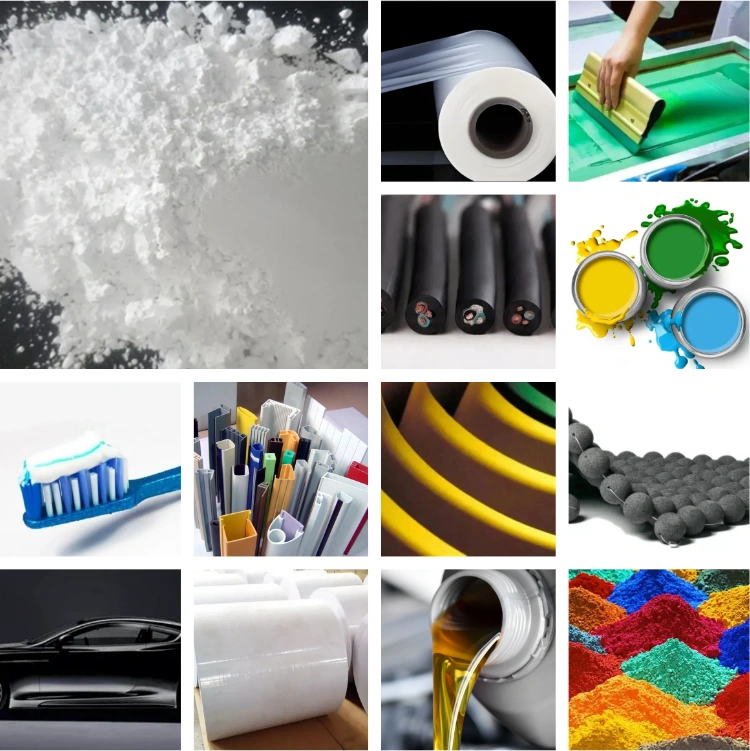

In the history of the plastics industry, calcium carbonate has long been regarded as a low-cost filler, valued mainly for reducing raw material costs. However, with breakthroughs in processing technology and the evolution of application demands, this traditional perception is being completely redefined. Today, calcium carbonate has transformed into a functional modifier that combines three […]

Calcium Carbonate Is Reshaping the Plastic Composites Industry Read More »