Raymond Mill

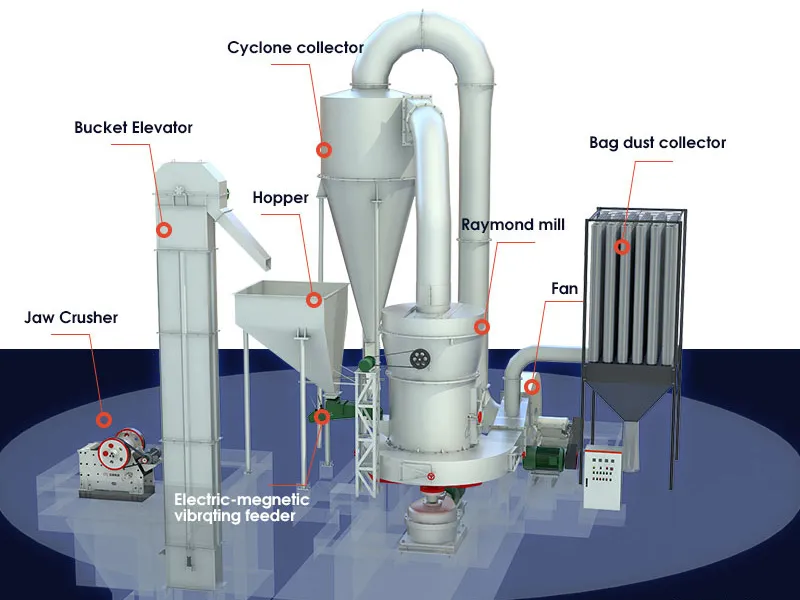

The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications. It is an efficient fine grinding machine for large-scale powder production.

Applied materials:

various non-flammable and explosive minerals such as gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, iron ore, etc.

Raymond mill working principle

- Raw materials are crushed into specified particle size by a jaw crusher, lift to the hopper by a bucket elevator, and then sent into the grinding chamber by a feeding machine quantitatively.

- Rotating shovels scoop up raw materials and project them between the rollers and the ring where the grinding takes place.

- The pulverized powder is blown to the classifier by the blower airflow for classifying. The oversized particles fall into the grinding chamber for regrinding. Qualified powders flow into cyclone collector through the classifier and are collected as end products.

- To ensure that the Raymond mill works under negative pressure, the increased airflow enters the pulse dust collector through the pipe and is discharged into the atmosphere after purification. The dust-free operation in the workshop is realized by the pulse collector.

Features of Raymond mill

1. Large output and high grinding efficiency

Outputs of 8 to176 tons per shift (8 hours). The finished powder is uniform in fineness, and the passing rate is as high as 99%.

2. Ability to produce powders of different particle sizes

Different uses of powder require different particle sizes. Therefore, the fineness of the Raymond mill can be adjusted arbitrarily between 0.173mm and 0.044mm. The achievable upper particle size is 800 mesh.

3. Low energy consumption

The Raymond pendulum mill achieves high requirements for grain size distribution easily and extremely energy efficiently, even in case of the highest demands regarding the fineness to be achieved.

4. Extremely robust and durable design

Less vibration due to integral gearbox increasing the mass of the mill and special designed anti-vibration device. Vibration reduction avoids cracking or damage to the frame and return box from long-term vibration and fatigue.

The important parts are made of high-quality steel, and the wearing parts are made of excellent wear-resistant materials to improve wear resistance.

5. Environmental protection

The good sealing performance of the equipment and the full-pulse dust collector ensure that the dust removal rate can reach 99%.

6. Automatic control

The electrical system adopts centralized control, and the grinding workshop can basically achieve unmanned efforts.

Calcium carbonate production related cases

Projects in these field

Calcium Carbonate Is Reshaping the Plastic Composites Industry

In the history of the plastics industry, calcium carbonate has

Calcium Carbonate — The “Grain of Industry”

In modern industrial systems, calcium carbonate (CaCO₃) is known as

Applications and Market Prospects of Ultra-fine Calcium Carbonate in Various Industries

According to different production methods, calcium carbonate can be classified

Key Technical Indices of Ultrafine Calcium Carbonate: Preparation by Grinding and Performance Requirements in Diverse Applications

The key technical specifications of ultrafine calcium carbonate—particle size, specific

What Are the Roles of Calcium Carbonate in Negative Electrode Materials

Driven by global energy transition and “dual-carbon” strategies, lithium-ion batteries

What Are the Best Methods for Ultrafine Calcium Carbonate Modification?

Ultrafine calcium carbonate refers to calcium carbonate particles with a

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS