Classification of Quartz Materials

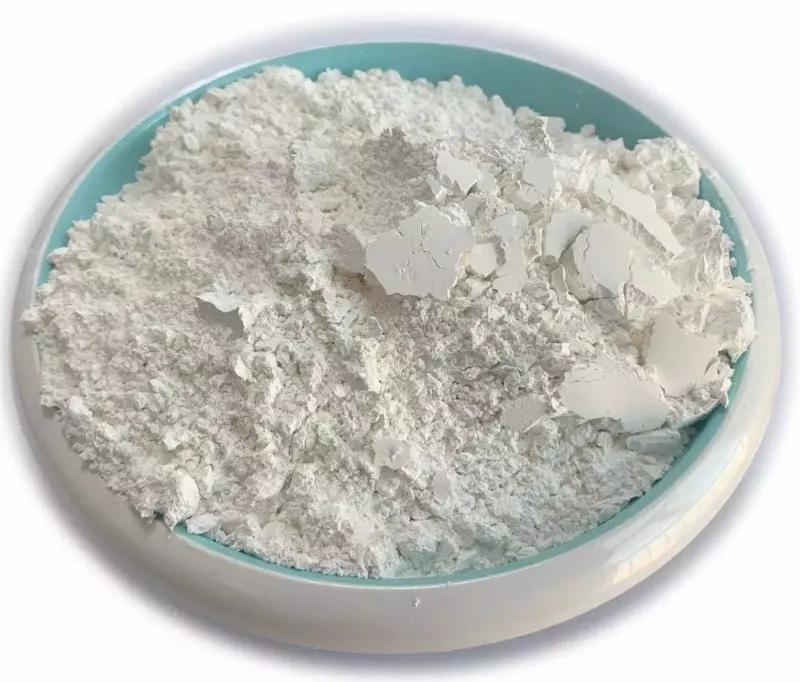

The journey of quartz from a raw mineral to a high-performance industrial material begins with precise quartz stone grinding and a deep understanding of its fundamental characteristics. This article provides a detailed overview of quartz material classification, its key physical and chemical properties, and its diverse industrial applications, highlighting why this material is indispensable in […]

Classification of Quartz Materials Read More »