Honeycomb Mill for Powder Coating

Principle and characteristics: when the equipment is running at high speed, it drives the strong air flow, so that the agglomerated powder particles stay in the stator of the equipment, and the stator is designed as a special groove. The strong vortices formed by wind pressure and wind speed will produce shear force, friction force and centrifugal force, which can quickly break the materials into single particles and reduce them to the original particle size or natural crystal particles.

Honeycomb Mill working principle

Honeycomb Mill, also known as Drying and dispersing machine, Multi-Rotor Dryer Mill, is jointly designed by our German technical experts and British technical experts. It can’t only achieve high-efficiency grinding, but also has excellent drying, dispersing and depolymerization, and modification functions. Its vertical shaft is equipped with multi-layer rotors, and max up to 10 layers of rotors. There are multiple evenly distributed blades on each rotor layer, slots formed by adjacent blades, like a honeycomb. The largest mill has 1600 slots. When the rotor rotates at a high speed, the airflow forms a turbulent flow in the slot. The mill liner is usually corrugated or multi-toothed, which promotes the formation of turbulent flow, and also enhances the grinding force, shearing force and impact force.

Features of Honeycomb Mill

- The rotor speed can be adjusted,up to 160m/s.

- The hot air temperature of drying design, up to 450℃.

- Set modifier injection nozzle on the mill cavity.

- The built-in classifying design can better control the particle size of the product.

- Strong shearing force, suitable for crushing tough and fibrous materials.

- Fast crushing speed, suitable for crushing heat-sensitive materials, and a cooling process system can be added for materials with extremely low melting points.

- According to different project needs, we have different blade designs and liner designs.

- Main material can be carbon steel, wear-resistant steel, stainless steel.

- Blade material can choose wear-resistant steel, stainless steel, tungsten carbide.

- Lining plate material can choose carbon steel, wear-resistant steel, stainless steel, alumina ceramics.

Honeycomb Mill Technical Parameters

| Parameter / Model | MRD-1 | MRD-2 | MRD-3 | MRD-4 | MRD-5 | MRD-6 |

|---|---|---|---|---|---|---|

| Grinding Motor Power(kW) | 45 | 90 | 160 | 200 | 315 | 450 |

| Classifying Motor Power (kW) | 5.5 | 7.5 | 15 | 22 | 37 | 55 |

| Blade(layer) | 3-6 | 4-7 | 5-8 | 5-8 | 5-8 | 6-10 |

| Blade speed(m/s) | 120 | 120 | 120 | 120 | 120 | 120 |

Projects

Projects in these field

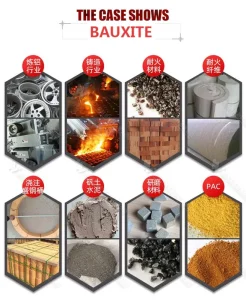

Process Comparison of Dry and Wet Grinding of Bauxite in Ball Mill

Bauxite is a non-metallic mineral mainly composed of aluminum oxide

Ball Mill + Classifier Production Line: An Efficient Solution for Zircon Sand Processing

Abstract Zircon sand, as an important industrial raw material, is

Saudi Arabia Coatings Show 2025: Innovation and Cooperation for Better Future

The Saudi Arabia Coatings Show, held from May 13 to

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS