Introduction

Amidst the robust growth of the iron and steel industry, steel slag, a primary solid waste generated during steel-making, has seen escalating volumes. According to industry statistics, approximately 100-150 kg of slag is produced per ton of steel manufactured. The accumulation of massive slag deposits not only occupies valuable land resources, but also poses contamination risks to soil, water bodies, and the atmosphere. Nevertheless, steel slag is far from worthless ‘waste’. Through scientific secondary treatment, it can be transformed into crucial raw materials for construction, metallurgy, etc, creating a win-win scenario for both economic returns and environmental benefits.

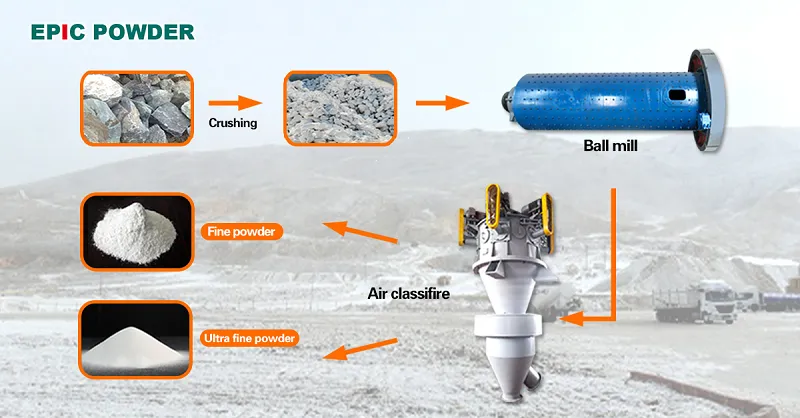

In particular, during the critical stages of secondary treatment of steel slag , ball mill and classifier play an irreplaceable and central role, providing robust equipment support for the resource utilization of steel slag.

Secondary treatment of steel slag: opening the door to solid waste resource utilization

The core objective of secondary treatment of steel slag is to fully extract the utilizable components from steel slag and process them into products meeting market demands. The entire treatment process mainly consists of four stages: pretreatment, grinding, classification, and post-treatment.

1. Pretreatment stage: iron removal and crushing

– Iron removal process

Equipment: electromagnetic roller, permanent magnetic separator

Principle: utilizing the magnetic difference between metallic iron and slag phase in steel slag, waste steel is recovered through magnetic adsorption (purity can reach over 90%), while reducing wear and tear of subsequent grinding equipment.

– Crushing

Equipment: jaw crusher → cone crusher → impact crusher (three-stage crushing)

Objective: Crush the particle size of steel slag from the initial 100-300mm to ≤10mm, preparing for subsequent grinding.

2. Grinding and refining stage

The grinding process is a key step in the secondary treatment of steel slag. It serves as the “core engine” for steel slag grinding, and it determines the particle size and performance of the final steel slag product. In this process, ball mill stands out with its strong grinding capability, becoming one of the preferred equipment in the industry.

2.1. Advantages of ball mill for steel slag grinding

In terms of grinding capacity, high wear-resistant grinding media driven by the rotation of the cylinder, continuously impacts and grinds steel slag. This process enables the gradual reduction of steel slag from larger particles to the required fineness. Whether producing steel slag powder for cement admixtures, which requires a specific surface area of 400-500 m²/kg, or steel slag aggregates for road base materials, the ball mill can precisely control the grinding process to meet the particle size requirements of different products.

2.2. Challenges and coping strategies of ball mill

| Characteristics of steel slag | Challenges | Ball mill strategies |

| High hardness, high wear resistance | The media and liner wear quickly, and the energy consumption is high | Use hard steel balls or ceramic balls, paired with wear-resistant ceramic/alloy liners. |

| Metallic iron mixed with slag | It is easy to cause the medium to stick together, affecting the grinding efficiency | Install a magnetic separation device for pre-treatment to separate metallic iron before grinding. |

| Strict particle size distribution requirements | The specific surface area needs to be controlled to adapt to building materials and other uses | (30%–50%)Adjust the speed (70%–85% of critical speed) and media fill rate (30%–50%) |

3. Precision classification stage

Advantages of classifier for steel slag classification

The material ground by the ball mill has a relatively wide particle size distribution, and it needs to be finely separated by a classifier to meet the strict requirements of different application fields. The classifier acts like a “gatekeeper” for the fine processing of steel slag, and it ensures that the products have uniform particle size and stable quality. For example, the particle size of steel slag powder can be controlled within the range of 1-45μm, and 90% of the particles are concentrated within 5-30μm. This can meet the strict requirements of high-end applications, e.g: high-performance concrete admixtures, for particle size uniformity.

In practical applications, ball mill and classifier do not operate independently in the secondary treatment of steel slag, but cooperate with each other and work together to form an efficient production system.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Our products include: powder grinding equipment, classification equipment, modification equipment and related auxiliary equipment. Among them, ball mill + classifier production line is widely used in the grinding and classification of various non-mineral powders. When used in the secondary treatment of steel slag, it not only improves grinding efficiency, but also reduces over-grinding and improves product quality, maximizing the utilization of resources.

In reality, our ball mill and classifier system has achieved remarkable results in several secondary treatment projects, significantly improving the production efficiency and finished product quality. This brings considerable economic benefits and a good market reputation to enterprises.

4. Post-processing and application adaptation

Activity Activation: the cementitious activity of steel slag is activated through steam curing (80-100°C) or by adding gypsum (3%-5% by weight), making it suitable for use as a cement blending material.

Magnetic separation and purification: the finely ground steel slag is magnetically separated again to recover fine-grained metallic iron (with a grade of ≥65%), which is used for recycling in steel-making.

Conclusion

The secondary treatment of steel slag transforms it from waste into valuable resources, representing a crucial direction for the iron and steel industry to achieve green and sustainable development. Qingdao Epic Powder Machinery Co., Ltd. takes equipment collaborative optimization as the core. Through the collaboration of ball mill and classifier, it facilitates the application of steel slag in high-performance building materials, metallurgical raw materials and other fields, while creating greater value for enterprises.

If you are purchasing ball mill, classifier or other powder processing equipment, or need relevant technical consultations, please contact Epic Powder. With professional technical support and reliable equipment quality, we provide comprehensive services throughout pre-sales, in-sales and after-sales stages, helping your powder processing reach higher standards and better market performance.