Resumo

A areia de zircão, como importante matéria-prima industrial, é amplamente utilizada em cerâmicas, materiais refratários, fundição e a indústria nuclear. Os altos requisitos de tamanho e pureza das partículas durante seu processamento tornam a moagem e a classificação elos essenciais. A linha de produção de moinho de bolas + classificador tornou-se gradualmente a tecnologia central do processamento de areia de zircônia devido à sua alta eficiência, economia de energia e capacidade de classificação precisa. Este artigo aborda o princípio de aplicação, as vantagens técnicas e os casos reais da linha de produção de moinho de bolas + classificador no processamento de areia de zircônia.

Características e desafios de processamento da areia de zircão

A areia de zircão (fórmula química: ZrSiO₄) é um mineral natural silicato de zircônio mineral com alta ponto de fusão (cerca de 2550°C), alta dureza (dureza Mohs 7,5) e excelente estabilidade química. No entanto, sua estrutura densa e tenacidade levam aos seguintes problemas nos processos tradicionais de britagem e moagem:

· Baixa eficiência de moagem: Equipamentos convencionais estão sujeitos a maior consumo de energia e maior desgaste do equipamento devido à alta dureza da areia de zircão.

· Dificuldade no controle do tamanho das partículas: Aplicações posteriores (como esmaltes cerâmicos) exigem distribuição uniforme do tamanho de partículas (geralmente D97≤45μm), mas é difícil obter classificação de alta precisão com equipamentos de moagem comuns.

Portanto, como alcançar a combinação de moagem eficiente e classificação precisa torna-se a chave para melhorar a qualidade do processamento da areia de zircão.

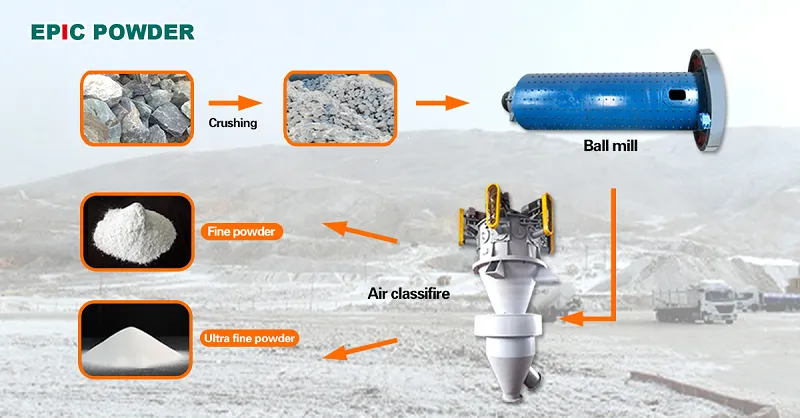

Fluxo de processo da linha de produção do moinho de bolas + classificador

A linha de produção do moinho de bolas e do classificador consiste em um moinho de bolas, equipamento de classificação (como um classificador de ar), um sistema de despoeiramento e um sistema de controle automático. O fluxo do processo é o seguinte:

① Britagem grosseira e pré-moagem

As matérias-primas são inicialmente britadas até menos de 5 mm por britador de mandíbula ou britador de impacto;

② Moagem fina em moinho de bolas

O moinho de bolas tritura ainda mais os materiais até o nível de mícron por meio do impacto e da ação de trituração de esferas de aço/esferas de cerâmica no cilindro.

Com base nas características da areia de zircão, pode-se adotar a moagem úmida ou seca. A moagem úmida pode reduzir a poluição por poeira, mas requer secagem subsequente; a moagem a seco evita a oxidação por meio da proteção contra gases inertes.

③ Classificação dinâmica e precisa

Após a moagem, o material entra no classificador de ar, onde a separação eficiente de partículas grossas e pó fino é alcançada através do equilíbrio entre força centrífuga e aerodinâmica. A precisão da classificação pode chegar a D97±2μm, e o controle do tamanho das partículas em vários níveis pode ser realizado ajustando a velocidade da roda classificadora ou o volume de ar.

④ Coleta e remoção de poeira

O pó fino qualificado é coletado pelo separador ciclônico ou filtro de mangas, e o pó ultrafino é reciclado para garantir uma emissão sem poeira.

Vantagens técnicas da linha de produção de moinho de bolas + classificador para processamento de areia de zircão

— Alta eficiência e economia de energia, melhorando a eficiência da produção

◈ O moinho de bolas e o classificador são interligados para formar um sistema de circuito fechado. Após a moagem, os materiais são peneirados pelo classificador, e as partículas grossas não qualificadas são devolvidas diretamente ao moinho de bolas para reprocessamento, reduzindo a retenção de material inválido e aumentando a eficiência da produção em mais de 30%.

◈ O moinho de bolas adota tecnologia de regulagem de velocidade de frequência variável para ajustar dinamicamente a velocidade de rotação de acordo com a dureza da areia de zircão, reduzindo o consumo de energia da unidade em 25%-30% em comparação com os processos tradicionais.

◈ Evite “moagem excessiva”: O classificador controla com precisão o tamanho de partícula qualificado, reduzindo o desperdício de energia causado pela moagem excessiva.

— Classificação precisa com forte capacidade de controle do tamanho de partículas

◈ A precisão de classificação do classificador de ar pode atingir D97±2μm, atendendo aos requisitos rigorosos de esmaltes cerâmicos (D97≤45μm), pós de grau eletrônico (D50≤10μm), etc.

◈ A tecnologia de classificação dinâmica garante uma distribuição estreita do tamanho de partículas do produto, aumentando a taxa de produto qualificado para mais de 95% e reduzindo significativamente a quantidade de material devolvido.

— Processo de baixa poluição para garantir alta pureza

◈ O moinho de bolas utiliza revestimentos cerâmicos e corpos de moagem de zircônia/alumina para substituir os revestimentos e esferas de aço tradicionais, evitando a introdução de impurezas metálicas como ferro e manganês. O teor de ferro do produto final pode ser controlado abaixo de 0,02%.

◈ A linha de produção totalmente fechada, integrada a um sistema de remoção de poeira, garante uma concentração de emissão de poeira ≤10 mg/m³. Isso atende aos padrões de proteção ambiental e, ao mesmo tempo, reduz a poluição da oficina.

◈ Na moagem a seco, gases inertes, por exemplo: nitrogênio, são introduzidos para evitar que a areia de zircão reaja com oxigênio em altas temperaturas, tornando-a adequada para cenários de aplicação de ponta sensíveis à oxidação (como aplicações na indústria nuclear).

Casos de aplicação prática

Máquinas de pó épico de Qingdao Co., Ltd. é um fabricante profissional especializado em equipamentos de processamento de pó, com décadas de experiência em produção e conhecimento técnico.

Nosso pprodutos incluem:

Equipamento de moagem: Moinho de bolas, moinho de jato, moinho classificador de ar, moinho de rolos, etc.

Classificação de equipamentos: Inclui 5 tipos de classificador de ar – HTS, ITC, CTC, MBS e TDC.

Equipamentos de modificação de superfície: Modificador de moinho de pinos, modificador de moinho de três rotores e modificador turbo-mill, etc.

Equipamento auxiliar: Gabinete de controle, filtro de bolsa, ventilador de sucção, etc.

Nossa linha de produção de moinho de bolas + classificador é amplamente utilizada no processamento de pós não minerais. Conta com tecnologia avançada, qualidade confiável e é amplamente elogiada pelos consumidores.

Caso real de Pó épico

Condição da matéria-prima

Matéria-prima: Areia de zircônia

Dureza de Mohs: 8

Densidade aparente: 2.700 kg/m3

Umidade: < 0,2%

Tamanho de alimentação: 99% ≤ 3mm

Requisito de produção

D95 45 µm: 2200 kg/h +/- 5%

D95 75 µm: 3000 kg/h +/- 5%

Nossa solução

Moinho de bolas com revestimento cerâmico: Φ2,2m × 6m + Classificador de ar ITC-3

Neste caso, nossa linha de produção de moinho de bolas + classificador teve um bom desempenho, atendeu aos requisitos dos clientes e estabeleceu uma boa base para a cooperação subsequente

Conclusão

A linha de produção de moinho de bolas + classificador oferece uma solução técnica confiável para o processamento de areia de zircônio, graças à sinergia entre moagem eficiente e classificação de precisão. Se você estiver adquirindo equipamentos para processamento de areia de zircônio ou outros equipamentos para processamento de pó, entre em contato com a Epic Powder. Teremos uma equipe profissional para acompanhar todo o processo, desde a consultoria técnica, design da solução, até a instalação e comissionamento do equipamento, treinamento do operador, bem como manutenção do equipamento e atualizações tecnológicas.

Contato Epic Powder, e deixe que nosso equipamento especializado capacite seu processamento de pó – para maior eficiência e economia de energia.